Using permanent magnets to reduce actuator force

In industry, often a case arises where a mass needs to be moved back and forth over a fixed distance i.e. point-to-point motion. In the semiconductor industry for example where throughput is one of the most important aspects, the time it takes to move back and forth has to become smaller and smaller. This leads to ever increasing acceleration which demands careful shaping of the motion profile. A 4th order trajectory planning is often used to obtain high performance smooth motion. In this motion profile the 4th derivative of the position with respect to time, the snap, is limited.

Still, if a certain mass has to be moved with ever increasing acceleration, the required force increases ($f=ma$). This leads to the situation were the moving mass of the actuator itself is the limiting factor to the obtainable acceleration. Nowadays the desired acceleration is often so large that no off-the-shelf actuator exist that has the required force density.

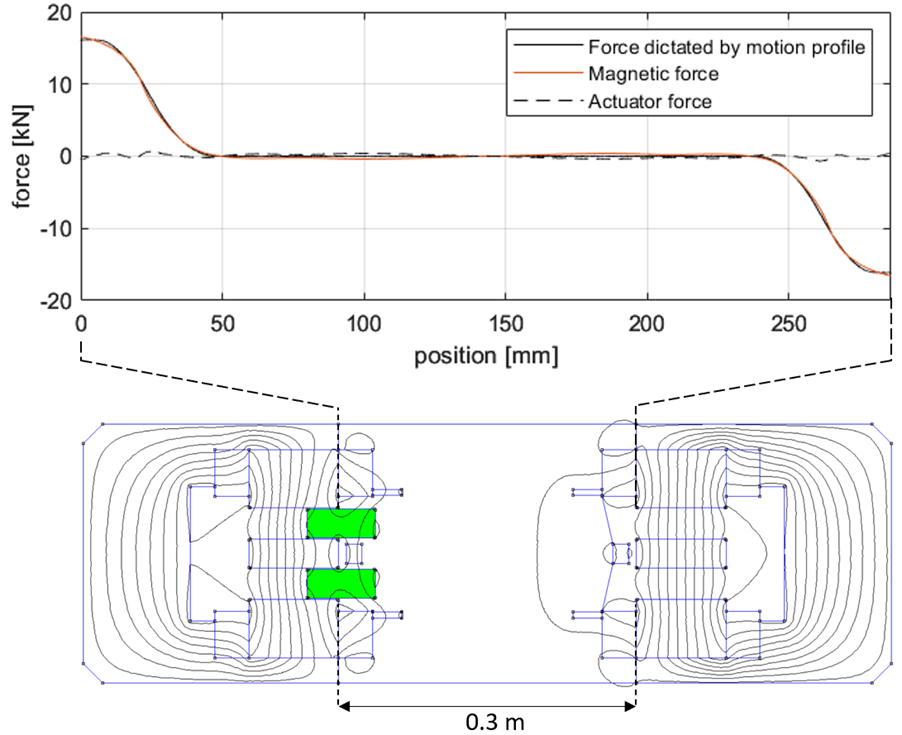

However, in the case of fixed distance point to point motion, the force – position graph is exactly known. Therefore a static force generation device (like springs) can be used to aid the actuator. Shaping the force – position behavior of springs to match the behavior dictated by the trajectory planning can lead to a mechanically complex system with undesired parasitic dynamics. It turns out that permanent magnets, when placed strategically, can closely match the desired force – position behavior. The remaining, much smaller, corrective force can be generated by an (existing off-the-shelf) actuator which can now be of much smaller size. An example can be seen in Figure 1 where a mass of 50 kg is accelerated and decelerated with 32g using a 4th order motion profile, and moved over a distance of 0.3m with a constant velocity of ~5m/s over a large portion of its stroke. The magnets provide the bulk of the required force of 16kN while the actuator now only has to provide ~0.8kN meaning a 20x reduction in actuator force.

Figure 1 – Strategically place stator magnets (blue) which interact with a mover magnet (green) to reduce the actuation force in fixed distance point to point motion.

Principle

- The force and energy required to move a mass in a fixed distance point-to-point fashion can be significantly reduced by strategically placed permanent magnets. The presented case shows a 20x reduction.

- An advantage of using permanent magnets over conventional springs is that it is a contactless method therefore avoiding undesired parasitic dynamics

Developed by

P. Rutgers (Demcon)