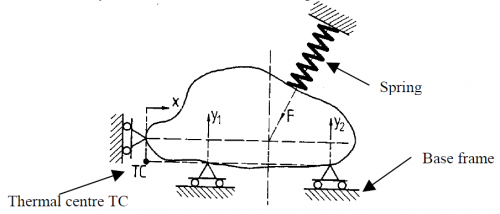

As shown with the gridiron pendulum, a design principle is to use materials with different coefficients of thermal expansion to compensate the thermal expansion to (almost) zero. Another commonly applied design principle is the so-called ‘thermal centre’. When a system is constrained in a statically determined manner, it is possible to define a centre: a point which does not displace under homogeneous thermal expansion. This is illustrated in figure 4, where a body is connected to a base frame with three contact points. A spring applies a force to ensure that the body is in contact with the three contact points. When the body or the base frame expands homogeneously, the thermal centre remains at the same location [Koster, 2008].

Figure 4: Principle of the thermal centre

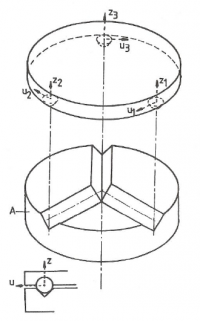

More practical ways to realise a thermal centre are shown in figure 5 and 6. In figure 5, a kinematic coupling is shown with three balls in three V-grooves. This principle is also called a ‘Kelvin-clamp’, named after its inventor Lord Kelvin (1824-1907). In this case the top and bottom plate have their thermal centre on the centreline.

Figure 5: Lord Kelvin’s clamp

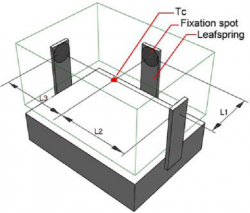

An object can be constrained using three leaf springs, as shown in Figure 6. If a temperature difference occurs between the object and its frame, the centre of expansion is at Tc. Because of the flexures, the temperature difference and/or the coefficient of thermal expansion can be large without serious effects [Giesen, 2003].

Figure 6: Thermal centre created with 3 leaf springs

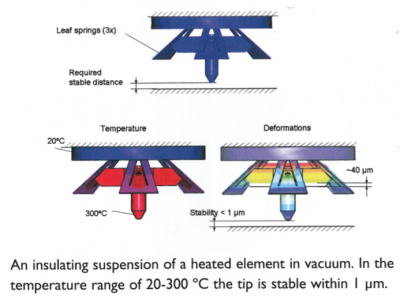

An application of the above mentioned principles is shown in figure 7, where a thermal centre with leaf springs is shown. Besides the thermal centre, the leaf springs are designed such, that a vertical (steady-state) temperature gradient does not lead to a change in the position of the tip. This principle is deducted from the gridiron pendulum, but is realised within the leaf springs. The leaf springs have two sections: the first section goes down (from the base plate) and the second section goes up. The leaf spring geometry is designed such that a vertical temperature gradient is compensated and the tip is stable within 1 µm.

Figure 7: Application of the thermal centre

Other design principles, such as the ‘thermal neutral rod’ and the ‘beds of nails’, are discussed in [Koster, 2008]. This list is not complete, and it would be appreciated if engineers would share other principles on this website.

If the selection of the right material, the application of the proper geometry and the use of design principles don’t lead to the desired system performance, it is possible to thermally condition the construction. This can be done passively or actively.