Thermocouples are based on the effect that the junction between two different metals produces a thermoelectric voltage which increases with temperature, also known as the Seebeck effect. Compared with resistance thermometers they offer the clear advantage of a higher upper temperature limit, up to several thousand degrees Celsius and they need no power to activated and therefore have no self-heatings effect that resistance sensors have. Their long-term stability is somewhat worse (a few degrees after one year), the measuring accuracy is slightly poorer (on the average +0.75% of the measurement range. They are frequently used in ovens, furnaces, flue gas measurements and other areas with temperatures above about 250°C.

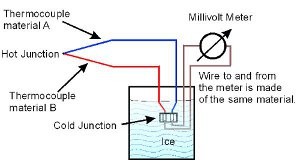

Because they measure only a temperature difference, the temperature difference of the cold-junction has to be known.

In practice a cold junction in melting ice is not really convenient. Older instruments used a thermostatically controlled junction box to control this cold junction temperature at a known value such as 50 ºC. Modern instruments use a thin film RTD at the cold junction to determine its temperature and calculate the measurement point temperature (www.enercorp.com).

In 1822, an Estonian physician named Thomas Seebeck discovered (accidentally) that the junction between two metals generates a voltage that is a function of temperature, and all thermocouples rely on the so-called ‘Seebeck effect’. Thermocouples are not, however, precision sensors: errors of 2 °C are typical. However, thermocouples have a wide temperature range (-200 to 2000 °C) and are often needed simply because alternative devices do not operate at the desired temperature. In addition, they are relatively low-cost and versatile.

Although almost any two types of metal can be used to make a thermocouple, a number of standard types are used (see table 2) because they possess predictable output voltages and large temperature gradients.

Standard tables show the voltage produced by thermocouples at any given temperature. For example, a K type thermocouple (the most popular) at 300 °C will produce 12.2 mV. This generation of a voltage, albeit small, does mean thermocouples (unlike RTDs and thermistors) are self-powered and require no excitation current. Unfortunately it is not possible to simply connect a voltmeter to the thermocouple to measure this voltage as doing so creates a second, undesired thermocouple junction. To make accurate measurements a technique known as cold junction compensation (CJC) is employed. All standard thermocouple tables allow for this second thermocouple junction by assuming that it is kept at exactly 0 °C. Traditionally, this was done with a carefully constructed ice bath. Maintaining an ice bath however is not practical for most applications; instead the actual temperature at the point of connection of the thermocouple wires to the measuring instrument is recorded and compensated for. Typically, cold junction temperature is sensed by a precision thermistor in good thermal contact with the input connectors of the measuring instrument. This second temperature reading, along with the reading from the thermocouple itself, is used by the measuring instrument to calculate the true temperature at the thermocouple tip. Understanding of CJC is important, as any error in the measurement of the cold junction temperature will lead to the same error in the measured temperature from the thermocouple tip.

On a general note, avoid subjecting the thermocouple connections — and indeed the measurement instrument — to sudden changes in temperature, such as those produced by drafts, as this will lead to errors.

As mentioned, different choices of metals for the thermocouple’s two conductors produce sensors with different characteristics. Table 2 summarises the most popular types.

| Thermocouple Type | Overall Range [°C] | Typical Accuracy* | Comments |

| Type B (Platinum / Rhodium) | 100 to 1800 | 5 °C (at 1000°C) | Suited for high temperature measurements. Unusually, type B thermocouples give the same output at 0 °C and 42 °C. This makes them useless below 50 °C. |

| Type E (Chromel / Constantan) | -200 to 900 | 1.7 °C | Type E has a high output (68 µV/°C) which makes it well suited to low temperature (cryogenic) use. Another property is that it is non-magnetic. |

| Type J (Iron / Constantan) | -40 to 760 | 2.2 °C | Limited range makes type J less popular than type K. J types should not be used above 760°C as an abrupt magnetic transformation will cause permanent decalibration. |

| Type K (Chromel / Alumel) | -200 to 1300 | 2.2 °C | Type K is the ‘general purpose’ thermocouple. It is low cost and popular. Sensitivity is approx 41 µV/°C. Use type K unless you have a good reason not to. |

| Type N (Nicrosil / Nisil) | -200 to 1300 | 2.2 °C | High stability and resistance to high temperature oxidation makes type N suitable for high temperature measurements without the cost of platinum (B,R,S) types. Designed to be an ‘improved’ type K, it is becoming increasingly popular. |

| Type R (Platinum / Rhodium) | -50 to 1760 | 1.5 °C | Suited for high temperature measurements up to 1600 °C. Low sensitivity (10 µV/°C) and high cost makes them unsuitable for general purpose use. |

| Type S (Platinum / Rhodium) | -50 to 1760 | 1.5 °C | Suited for high temperature measurements up to 1600 °C. Low sensitivity (10 µV/°C) and high cost makes them unsuitable for general purpose use. Due to its high stability type S is used as the standard of calibration for the melting point of gold (1064.43 °C). |

| Type T (Copper / Constantan) | -200 to 400 | 1 °C | Best accuracy of common thermocouples, often used for food monitoring and environmental applications. |

Thermocouples are made of thin wire to minimize thermal shunting and increase response times. This thin wire causes the thermocouple to have a high resistance that can cause errors due to the input impedance of the measuring instrument. A typical exposed junction thermocouple with 32 AWG wire (0.25 mm diameter) will have a resistance of about 15 Ω/m. If thermocouples with thin leads or long cables are needed, it is worth keeping the thermocouple leads short and then using thermocouple extension wire (which is much thicker and has a lower resistance) to run between the thermocouple and measuring instrument. It is always good practice, before you make precision measurements using thermocouples, to check the input impedance of the measuring instrument and also the resistance of each thermocouple.

If you need to increase the length of the leads from a thermocouple, use only the correct type of thermocouple extension wire. Using any other type of wire will introduce an undesirable thermocouple junction. Ensure any plugs, sockets or terminal blocks used to connect the extension wire are made from the same metals as the thermocouples and correct polarity must be observed at all times.

With signal levels from thermocouples measuring only microvolts, noise pickup can be a problem. Noise from stray electrical and magnetic fields is typically orders of magnitude higher than the signal level. Most measuring instruments reject any common mode noise (signals which are the same on both wires) — but this rejection is not perfect, so it makes sense to minimise the noise where possible. This can be done by routing wires away from noisy areas and twisting the two (insulated) leads of the thermocouple cable together to help ensure both wires pick up the same noise. If operating in an extremely noisy environment (such as near a large motor) it is worth considering using a screened extension cable.

A final note on thermocouples: decalibration. This is the process of unintentionally altering the makeup of the thermocouple. The usual cause is the diffusion of atmospheric particles into the metal at the extremes of the operating temperature range. Another cause is impurities and chemicals from the insulation diffusing into the thermocouple wire. If operating at high temperatures, check the specifications of the probe insulation. In addition, it is always good practice to use thermocouples with insulated junctions as this helps protect against oxidation and contamination.