Introduction

In precision engineering, thermal effects have always been important in reaching high precision.

In precision engineering, thermal effects have always been important in reaching high precision. However, over the years little attention has been given to this subject. In precision systems, thermal effects have a large influence on the desired accuracy and throughput, especially when these systems have to perform under extreme thermal conditions (for example, vacuum or cryogenic). Therefore, it is important to give this aspect sufficient attention in the design phase.

Pendulum clocks

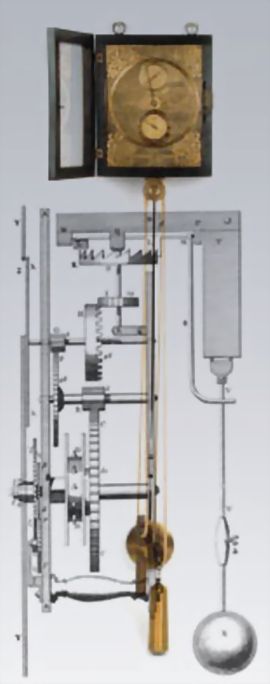

One of the first position systems where thermomechanics was important, is the clock. From its invention in 1656 by Dutchman Christiaan Huygens until the 1930s, the pendulum clock, as shown in Figure 1, was the world’s most precise timekeeper. A pendulum clock is a clock that uses a pendulum, a swinging weight, as its timekeeping element. Huygens was inspired by investigations of pendulums by Galileo Galilei beginning around 1602. Galileo discovered the key property that makes pendulums useful timekeepers: isochronism. This means that for small swings the period of swing of a pendulum is approximately the same for different sized swings. Successive swings of the pendulum, even if changing in amplitude, take the same amount of time. The introduction of the pendulum, the first harmonic oscillator used in timekeeping, increased the accuracy of clocks enormously, from about 15 minutes per day to 15 seconds per day. The period of swing of a simple gravity pendulum depends on its length, the acceleration of gravity, and to a small extent on the maximum angle that the pendulum swings away from vertical, which is called the amplitude. It is independent of the mass of the bob. If the amplitude is limited to small swings, the period T of a simple pendulum, the time taken for a complete cycle, is:

where L is the length of the pendulum and g is the local acceleration of gravity.

The largest source of error in early pendulums was slight changes in length due to thermal expansion and contraction of the pendulum rod with changes in ambient temperature. This was discovered when people noticed that pendulum clocks ran slower in summer, by as much as a minute per week. A pendulum with a steel rod will expand by about 11.3 parts per million with each degree Celsius increase ([ppm/°C]), causing it to lose about 0.5 seconds per day per degree of temperature change.

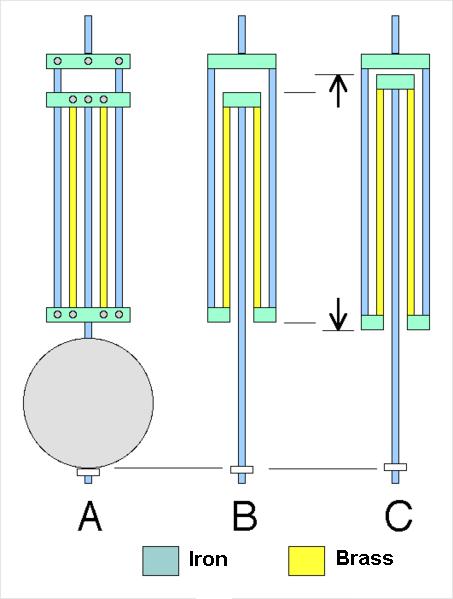

The most widely used compensated pendulum was the gridiron pendulum, shown in Figure 2, invented in 1726 by British clockmaker John Harrison. The gridiron pendulum didn’t change in length with temperature, so that its period of swing stayed constant with changes in ambient temperature. It consists of alternating brass and iron rods, assembled such that their different thermal sensitivities cancel.

Around 1900 low thermal expansion materials were developed which, when used as pendulum rods, made elaborate temperature compensation unnecessary. In 1896 Charles Édouard Guillaume invented the nickel steel alloy Invar. Invar has a Coefficient of Thermal Expansion (CTE) of around 1.2 [ppm/°C], resulting in pendulum temperature errors of about 0.05 seconds per day. This residual error could be compensated to zero with a few centimeters of aluminium under the pendulum bob, compensating the expansion of the Invar rod. Later fused silica was used which had even lower CTE (0.55 [ppm/°C]).