Chapter 2 - Design using flexures

Chapter 10 - Design for manufacturability

Flexure assembly using Dove tail clamps

Problem description

Flexure based mechanisms often contain multiple basic flexure elements as building blocks, for example leafsprings or wire-flexures. Assembly of these elements without hysteresis and with proper alignment can be challenging. To avoid these assembly difficulties, flexure mechanisms are often created as a monolithic structure which generally leads to complex geometrical shapes. This requires advanced manufacturing methods, such as EDM, and processing in multiple orientations, significantly increasing cost. A potential method to reduce cost is by assembling flexure mechanisms from individual parts while maintaining proper alignment and low hysteresis is using Dove tail clamps.

Concept: Dove tail clamps

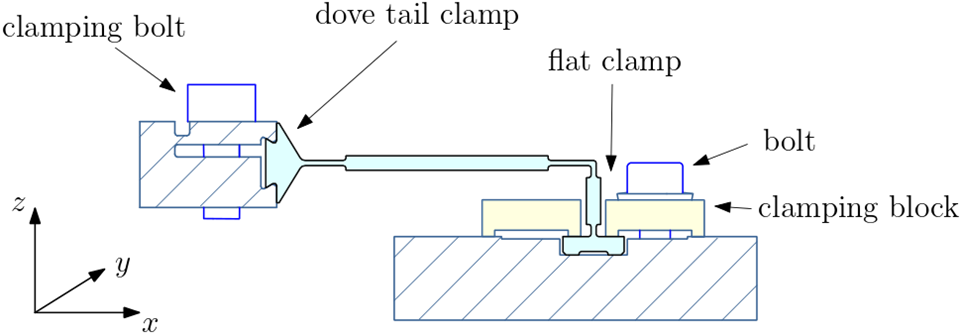

A common method of assembling flexure mechanisms is by clamping. Here, it is important to achieve sufficient surface pressure in the clamping contact to avoid hysteresis [1]. In this example, a folded leafspring is clamped onto a two rigid elements, sown in Figure 1. On one end of the leaf spring a dove tail clamp is used to clamp the leafspring to a rigid body. The dove tail defines the position and orientation of the leafspring. A dove tail shape is created on the leafspring by wire EDM. The counterpart has a milled dove tail groove. The vertical surfaces of the dove tail provide a locating function. A number of bolts is used to preload the dove tail and generate the required clamping force.

At the other end of the leaf spring clamping blocks are used to clamp the leafspring downward onto its counter surface. Notice the recess in the thickened leafspring end to concentrate the stress and thereby reduce hysteresis [1]. This flat clamp only imposes the z, Rx and Ry direction. The alignment of the flexure in the x, y and Rz direction can be left to minimizes assembly stress, or can be prescribed by additional alignment tools. Note the moment of the bolt of the clamping blocks is kept away from the flexure clamp.

Figure 1. Cross sectional view of the dove tail clamp concept and the flat clamp concept.

References

- M.J.R Soemers. Design Principles for Precision Mechanisms. T-Pointprint, Enschede, first edition, 2010.

Developed by

- Rick Baade (VDL ETG)

Dove tail design in collaboration with Vermo B.V. (Helmond)