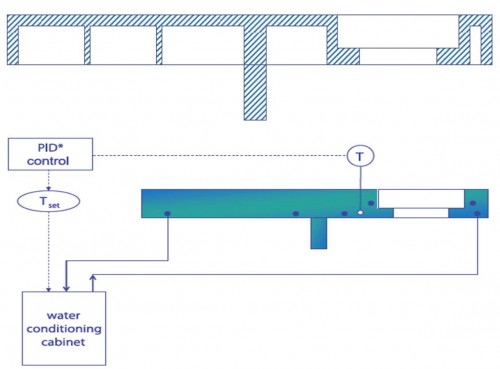

The most common applied active technique is cooling, which can be for instance water, oil or air cooling. This can be done open and closed loop. Besides using channels, it is also possible to apply showers to thermally condition a structure. As described in [Box, 2006], an metrology frame made out of Invar plates, which was used for an ASML wafer stepper was replaced by a solid aluminium frame with closed loop water cooling (see Figure 9). Because of the thermal properties of aluminium, active water conditioning is highly effective. The internal conduction is high enough to enable excellent conditioning of the entire frame. The relatively large heat capacity of aluminium ensures that temperature fluctuations, of the environment as well as the cooling water, are dampened very well. Next to the above mentioned advantages, the cost price and lead time are significantly reduced.

Figure 9: Traditional invar sheet metal metrology frame versus solid aluminium metrology frame

Besides conditioning techniques involving gases or liquids, it is also possible to apply thermal actuators. A simple example is placing a heating element next to a drive system. When the drive system is powered, heat will be dissipated. By applying a control loop, the heating element guarantees that always the same amount of heat will be dissipated, in case the driving system dissipates less power. In this case, heat dissipation remains constant and the construction will reach a thermal steady-state with the corresponding thermal stability.