Resistance thermometers, also called resistance temperature detectors or resistive thermal devices (RTD’s), are temperature sensors that exploit the predictable change in electrical resistance of some materials with changing temperature.

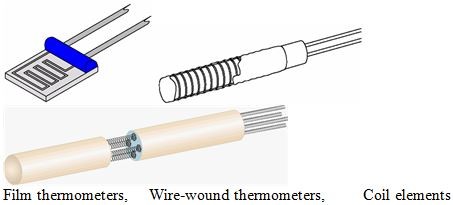

Resistance thermometer elements are available in a number of forms.

The most common are:

- Unsupported wirewound – a wire coil minimally supported within a sealed housing filled with an inert gas. These sensors are used up to 961.78 °C and are used in the SPRT’s that define ITS-90

- Wirewound in a ceramic insulator – a wire coil sealed in a ceramic cylinder, works with temperatures to 850 °C

- Wire encapsulated in glass – wire around glass core with glass fused homogeneously around. More protection to the detecting wire than other forms and resists vibration, but smaller usable range

- Thin film – platinum film on ceramic substrate, small and inexpensive to mass-produce, fast response to temperature change, but smaller temperature range and not capable of the highest accuracy

Wiring configurations

Resistance thermometers can be measured in different wiring configurations, depending to the accuracy required.

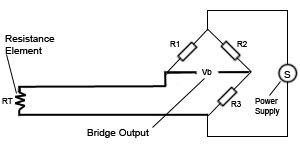

Two-wire configuration

The simplest resistance thermometer configuration uses two wires. It is only used when high accuracy is not required, as the resistance of the connecting wires is added to that of the sensor, leading to errors of measurement. The wire resistance and sensor are added together which is interpreted by the electronics as an increased temperature This applies equally to balanced bridge and fixed bridge system.

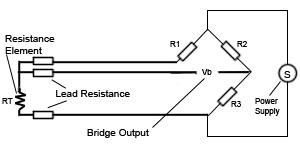

Three-wire configuration

In order to minimize the effects of the lead resistances, a three-wire configuration can be used. Using this method the two leads to the sensor are on adjoining arms. There is a lead resistance in each arm of the bridge so that the resistance is cancelled out, so long as the two lead resistances are accurately the same.

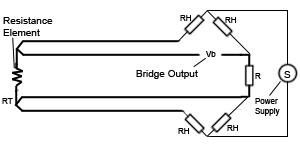

Four-wire configuration

The four-wire resistance thermometer configuration increases the accuracy and reliability of the resistance being measured: the resistance error due to lead wire resistance is zero. In the diagram above a standard two-terminal RTD is used with another pair of wires to form an additional loop that cancels out the lead resistance. This 4-wire Kelvin connection provides full cancellation of spurious effects; cable resistance of up to 15 Ω can be handled.

PTC’s

A positive temperature coefficient (PTC) refers to materials that experience an increase in electrical resistance when their temperature is raised. Materials which have useful engineering applications usually show a relatively rapid increase with temperature, i.e. a higher coefficient. The higher the coefficient, the greater an increase in electrical resistance for a given temperature increase.

Metals – All metals produce a positive change in resistance for a positive change in temperature. This, of course, is the main function of an RTD. As we shall soon see, system error is minimized when the nominal value of the RTD resistance is large. This implies a metal wire with a high resistivity. The lower the resistivity of the metal, the more material we will have to use.

| Metal | Resistivity [Ohm/cmf] (cmf = circular mil foot) |

| Gold | 13 |

| Silver | 8.8 |

| Copper | 9.26 |

| Platinum | 59 |

| Tungsten | 30 |

| Nickel | 36 |

Because of their lower resistivities, gold and silver are rarely used as RTD elements. Tungsten has a relatively high resistivity, but is reserved for very high temperature applications because it is extremely brittle and difficult to work.

Copper is used occasionally as an RTD element. Its low resistivity forces the element to be longer than a platinum element, but its linearity and very low cost make it an economical alternative. Its upper temperature limit is only about 120ºC.

The most common RTD’s are made of either platinum, nickel, or nickel alloys. The economical nickel derivative wires are used over a limited temperature range. They are quite non-linear and tend to drift with time. For measurement integrity, platinum is the obvious and most common choice.