Chapter 4 - Design for dynamic stiffness

Bed of Nails increase vibration mode frequencies

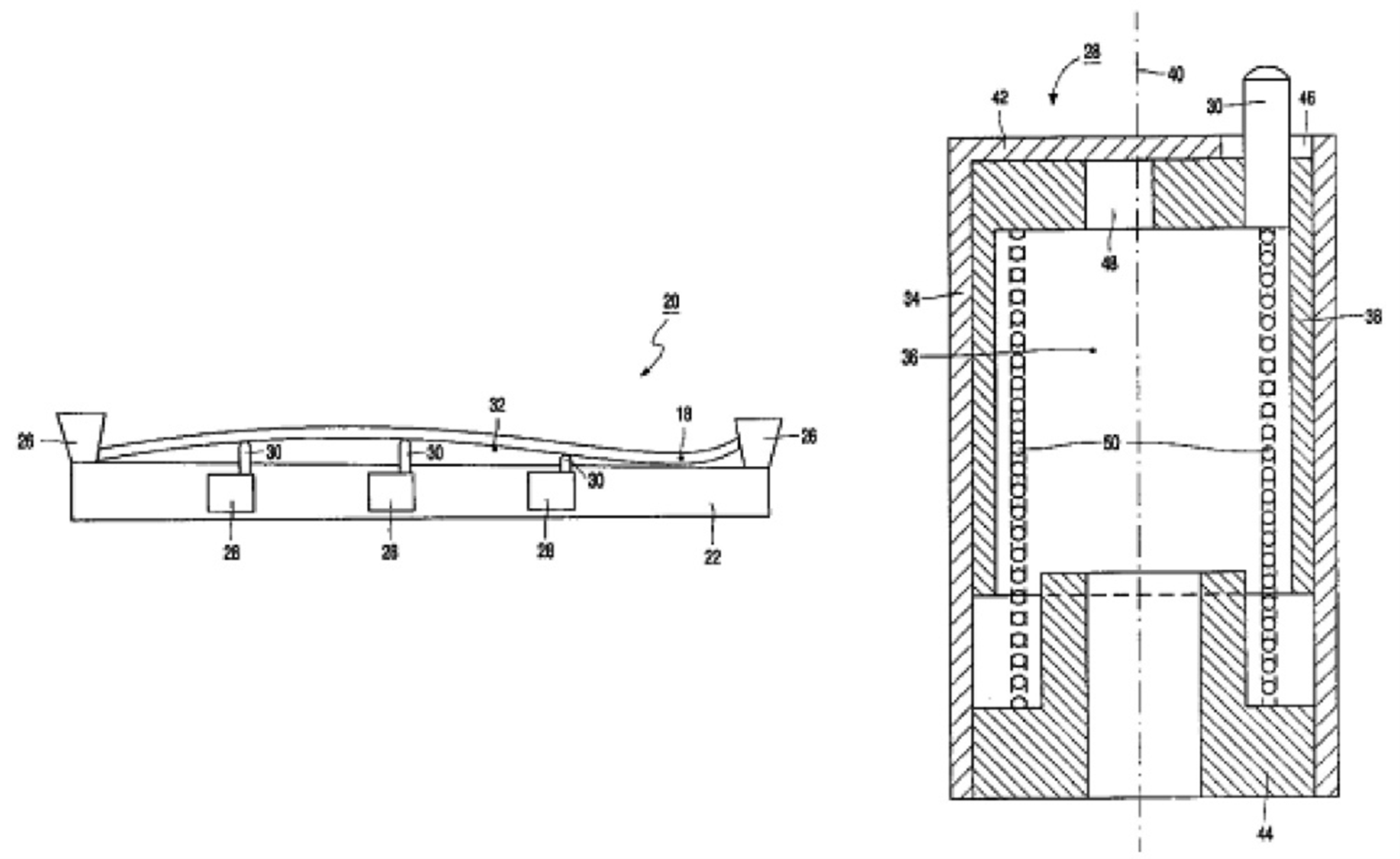

A statically determinate three point support of a wafer gives rise to a number of low frequency vibrations modes, which hampers high resolution electronmicroscope imaging. It is difficult to vertically support a wafer by more than three fixed supports. This is due to the flatness tolerance of the wafer, which in turn limits the option of generating a more contact support by demanding a lower flatness tolerance of the waferholder. The wafer will be in contact with the holder at only three points. Over large parts of the wafer there will be a gap between the wafer and the holder, allowing for low vibration mode frequencies to arise in the wafer. Even though these amplitudes may be as small as only several picometers, they can deteriorate for example the image of the wafer in an electron microscope. These modes shapes in the wafer can be alleviated by introducing many more supports in the shape of guided pins, 30 for instance, which are very lightly pressed against the wafer.

|

| Figure 1. (left) The support of an unflat wafer. (right) A sketch of an individual nail with eccentric pin to create friction in the guidance of the cylinder. |

Principle

A wafer can be well supported vertically by 30 guided pins, which are very lightly pressed against the wafer, shown in Figure 1 and 2. It is crucial that the guidance of each of the pins introduces a small and limited amount of friction to lock each pin by Hertzian contact. Only during the mounting of the wafer all the guided pins slide down by the mass of the wafer until the three fixed supports contact the wafer are reached, just as it would be without the guided pins. The Hertzian contacts are only very lightly loaded because (1) only a fraction of the wafer mass is required to move a guided pin over the full range, and (2) the eccentric loading of the spring under a single pin creates only a limited normal force at the friction contact point, see Figure 1. Even though the Herzian contacts are lightly loaded, they essentially do not slip under the picometer sized vibrations, and therefore the sliding pins stiffly lock the arbitrary shape of the un-flat wafer. This in turn removes the lowest vibration mode frequencies with usually the largest amplitudes from the wafer, allowing for high resolution electron microscope imaging.

Conclusion

A bed of sliding nails alleviates low frequency vibration modes in common unflat thin plates. The plate is supported by three fixed contacts, and many guided nails which provide stiff supports at small vibrations, by locking using only a small amount of friction in their guiding.

Developed by Thermo Fisher Scientific

- A. Visscher

Reference:

[1] A Visscher, Object carrier for a particle-optical apparatus, Patent: US 6,593,581, FEI Company, Granted 2003.

[2] L. van Beukering & H. van Eerden, Wim van der hoek, Een constructief leven, DSPE, ISBN 978-90-829-6583-4, eerste druk nov. 2020, pp. 186