NEWS 12 September 2023

Preserving precision in PEEK printing

Bond3D’s unique 3D-printing technology has vastly expanded the application scope of PEEK.

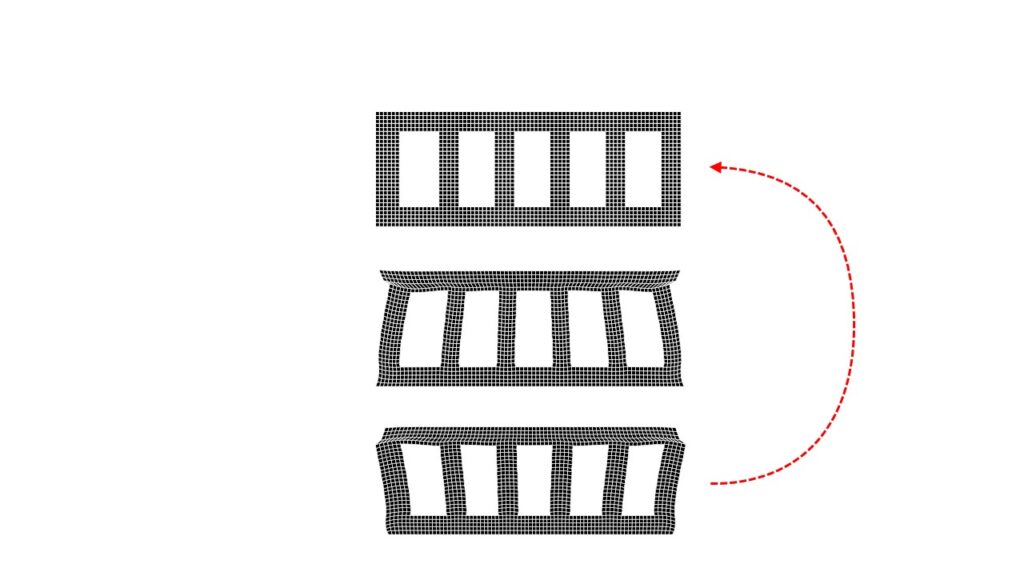

High-strength, isotropic parts can be produced from this high-performance polymer in a pressure-controlled, voidless printing process. Due to PEEK’s high melt temperature and high coefficient of thermal expansion, thermal effects play a significant role. Therefore, to ensure the dimensional accuracy of the printed parts, Bond3D has developed an advanced shrink-compensation procedure, as described in this Mikroniek article. The achievable accuracy conforms to the ISO 2768 standard for machining tolerances. (Image courtesy of Bond3D).