Wafer-handler systems engineering and magnetic bearing design

A systems engineering approach to the design of a wafer handler is presented in this Mikroniek article, starting with an introduction to wafer handling, followed by the corresponding requirements and...

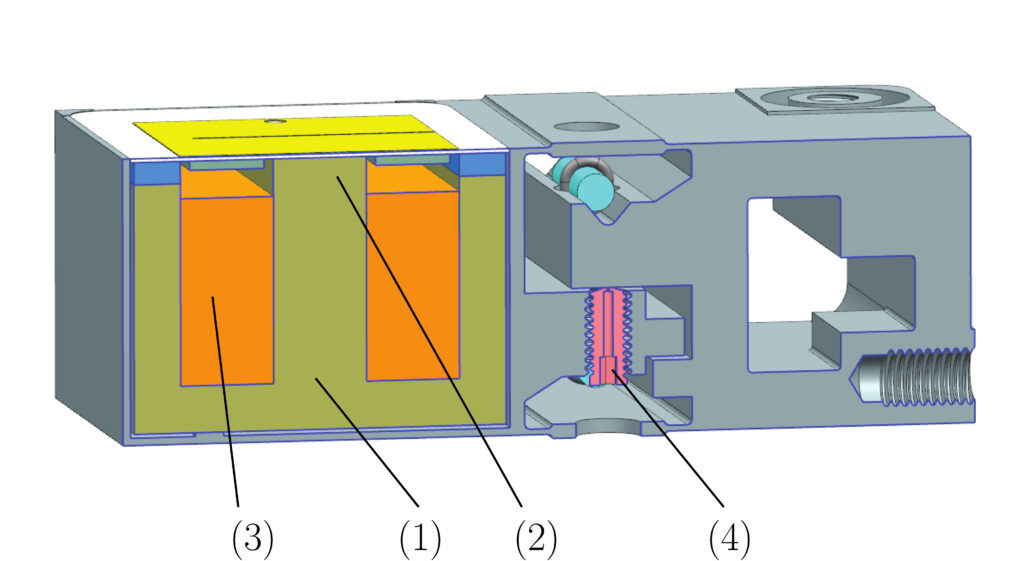

A systems engineering approach to the design of a wafer handler is presented in this Mikroniek article, starting with an introduction to wafer handling, followed by the corresponding requirements and lastly common system architectures. Regarding wafer-handling robots, the conclusion is that the moving robot mass increases when contamination requirements become more stringent. Moreover, robotic concepts containing a linear stroke can improve stiffness and reduce mass at the cost of contamination-sealing complexity. To conclude, the design and realisation of a low-end, low-cost magnetic bearing for high-cleanliness robotic applications is discussed.