NEWS 28 April 2022

Nanometer precision in practice

In 2020, Nobby Assmann won a Zeiss #measuringhero Award for the smallest measured object on a coordinate measuring machine: 0.4 mm x 0.4 mm x 0.03 mm.

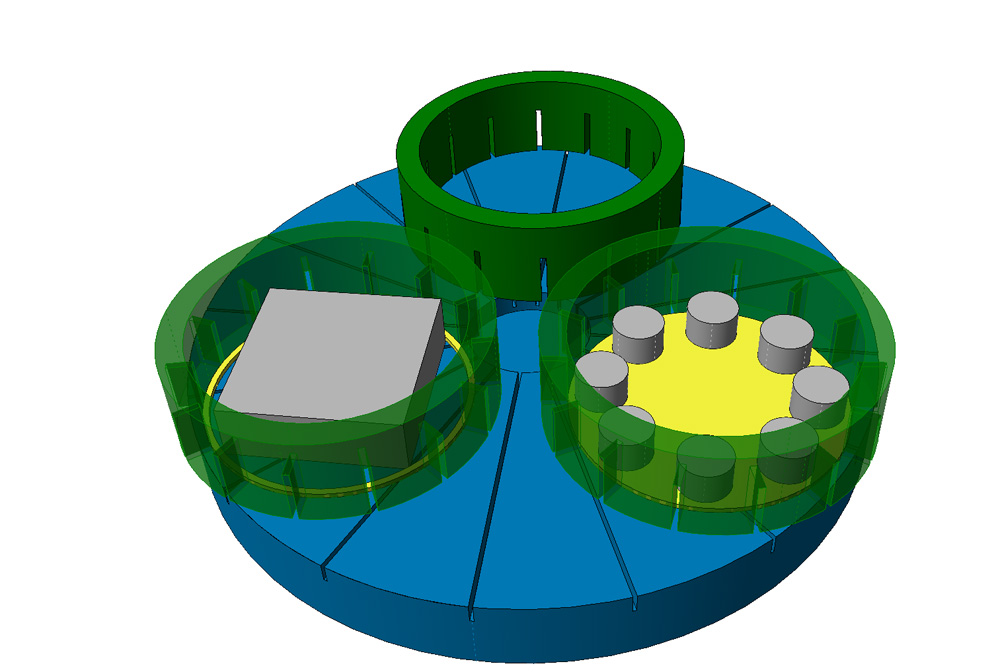

The next year, he won another award, this time for the smoothest surface, with a surface roughness of Ra 540 pm and Rz 3.1 nm. The surface was finished by lapping, flat polishing and chemical mechanical planarisation; three extremely precise processes. This Mikroniek article descibes what exactly are these processes and what is it that drives this technician. (Image courtesy of Assmann Verspaningstechniek)