Active contamination control for equipment and substrates

High-end manufacturing equipment has to support increasing levels of cleanliness.

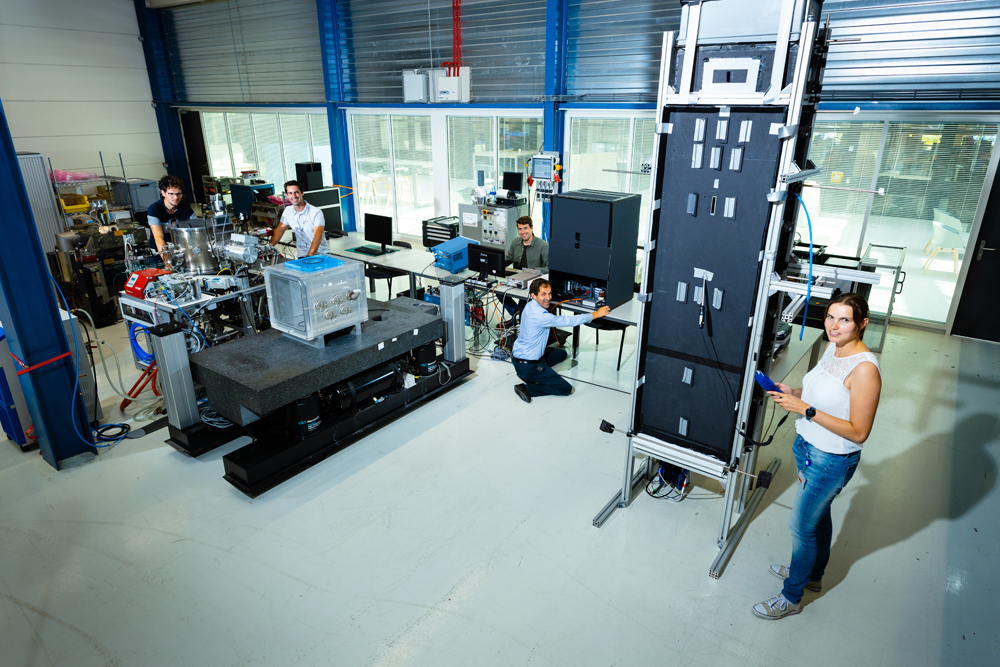

First-tier high-tech system supplier VDL ETG is pro-actively developing capabilities in product design as well as in production process design to support increasing requirements on cleanliness. Where knowledge gaps exist, VDL ETG supports research to further the state-of-art, for example in the ACCESS project: Active Contamination Control for Equipment and SubstrateS. In this project, VDL ETG and Eindhoven University of Technology (TU/e) work together as a multidisciplinary team, to deepen the fundamental understanding of generation, transport and removal of particle contamination. This Mikroniek article presents an overview of the project.