Lunch Lecture January hosted by NTS – Group

“Verification and manufacturability of robust mass damping (RMD)” ynamical performance of undamped tuned mass dampers (TMD) is sensitive to mistuning, both in forcing frequency and natural frequency. This design of...

About this event

“Verification and manufacturability of robust mass damping (RMD)”

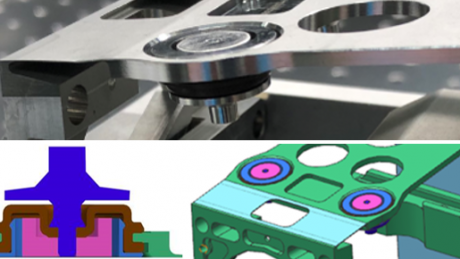

ynamical performance of undamped tuned mass dampers (TMD) is sensitive to mistuning, both in forcing frequency and natural frequency. This design of a robust mass damper (RMD) can handle a large range of operational excitation and complex damping due to variation in visco-elastic material, geometry and temperature. Excitation originates from a high-acceleration stage and resonance in leaf spring guiding. Manufacturing challenges were to integrate the RMD in the leafsprings robustly, e.g. operator independent assembly, and to keep to simple geometry to allow standard moulds for the viscoelastic. We will discuss both the design process and experimental results.

The speakers will be: Reinout Veldhuizen en Ivan van der Kroon

We will start at 12:02pm on January 17 2022

Please send an email to info@dspe.nl if you are interested in this Lunch lecture.

The Netherlands

DigitalReferences

For lumped systems consisting of different frictions and stiffnesses, there has been confusion in literature about hysteresis curves and virtual play for many decades.

Read more

In mid-April, the second edition of the Manufacturing Technology Conference and the fifth edition of the Clean Event were held together, for the first time, at the Koningshof in Veldhoven (NL).

Read more

Particle contamination monitoring and cleanliness control are fundamental to micromanufacturing processes across diverse industries to achieve cost-effective production of high-quality and reliable microscale devices and components.

Read more