Lunch Lecture April hosted by Philips Innovation Services

Identification & Control of Thermo-Electric-Coolers Consumer electronics, and professional equipment alike, become increasingly reliant upon the ability for precise thermal management. As such, thermal control is gaining more attention in...

About this event

Identification & Control of Thermo-Electric-Coolers

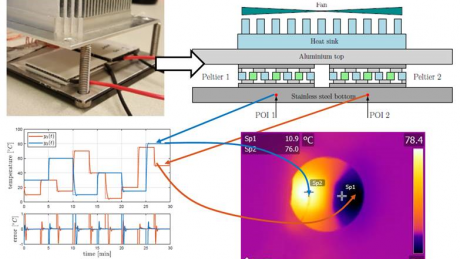

Consumer electronics, and professional equipment alike, become increasingly reliant upon the ability for precise thermal management. As such, thermal control is gaining more attention in the fields of product design and (high) precision engineering. Thermo-electric coolers (TEC) or Peltier elements can be used both for heating and for cooling, making them ideal as thermal actuators. In this presentation, two identification methodologies (white vs black box) are discussed that allow for efficient modelling of the peltier thermo-dynamics. Furthermore, control of a setup with two individually controllable TECs will be extensively discussed.

The speaker will be Rob van Gils, Sr. Technologist / Competence Leader Thermal & Flow, Philips Innovation Services

We will start at 12:03pm and it will end at 12:30pm

If you are interested in this Lunch Lecture please send an email to info@dspe.nl.

The Netherlands

DigitalReferences

For lumped systems consisting of different frictions and stiffnesses, there has been confusion in literature about hysteresis curves and virtual play for many decades.

Read more

In mid-April, the second edition of the Manufacturing Technology Conference and the fifth edition of the Clean Event were held together, for the first time, at the Koningshof in Veldhoven (NL).

Read more

Particle contamination monitoring and cleanliness control are fundamental to micromanufacturing processes across diverse industries to achieve cost-effective production of high-quality and reliable microscale devices and components.

Read more