DSPE Lunch lecture hosted by Nobleo Technology September 6

Direct drive or Indirect? That’s the question. The lecture will be given by Niels Koenraad, Nobleo Technology. Typical struggles in actuator selection are to balance upsides, such as high...

About this event

Direct drive or Indirect? That’s the question.

The lecture will be given by Niels Koenraad, Nobleo Technology.

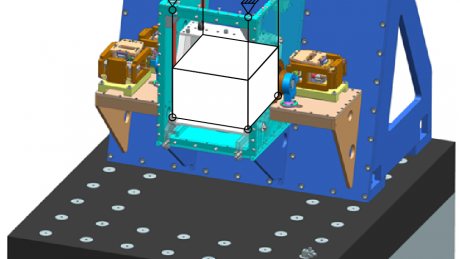

Typical struggles in actuator selection are to balance upsides, such as high force, with the downsides of additional mass, volume and availability. Adding a transmission has its own downsides, such as friction, backlash and hysteresis. But what if a gear ratio can be created with the aid of flexure mechanics, eliminating all these downsides? How does one deal with the parasitic movements, the own guiding stiffness, dynamics and motor choice in a static use case? In this presentation, a pragmatic implementation is presented of an (in)direct-drive actuator that is self-guided and compliant in multiple passive directions to be used in a steady-state multi-axis kinematically coupled system.

We will start at 12:02pm on September 6.

Please send an email to info@dspe.nl if you are interested in this Lunch lecture.

The Netherlands

DigitalReferences

For lumped systems consisting of different frictions and stiffnesses, there has been confusion in literature about hysteresis curves and virtual play for many decades.

Read more

In mid-April, the second edition of the Manufacturing Technology Conference and the fifth edition of the Clean Event were held together, for the first time, at the Koningshof in Veldhoven (NL).

Read more

Particle contamination monitoring and cleanliness control are fundamental to micromanufacturing processes across diverse industries to achieve cost-effective production of high-quality and reliable microscale devices and components.

Read more