Design for stability

Stability in high tech systems concerns position stability of components or modules in a system in time wrt each other or a reference. Generally the instability is defined as a slow long term effect and the instability effect is mostly referred to as Drift or Creep. Typical timescale is >> 1 sec. Drift can be periodic and return to a start or equilibrium status.

Fast non periodic sudden position changes occur due to release of any kind of internal stress or an external force which results in a position shift of a structure. These instability effects are called snapping or glitching.

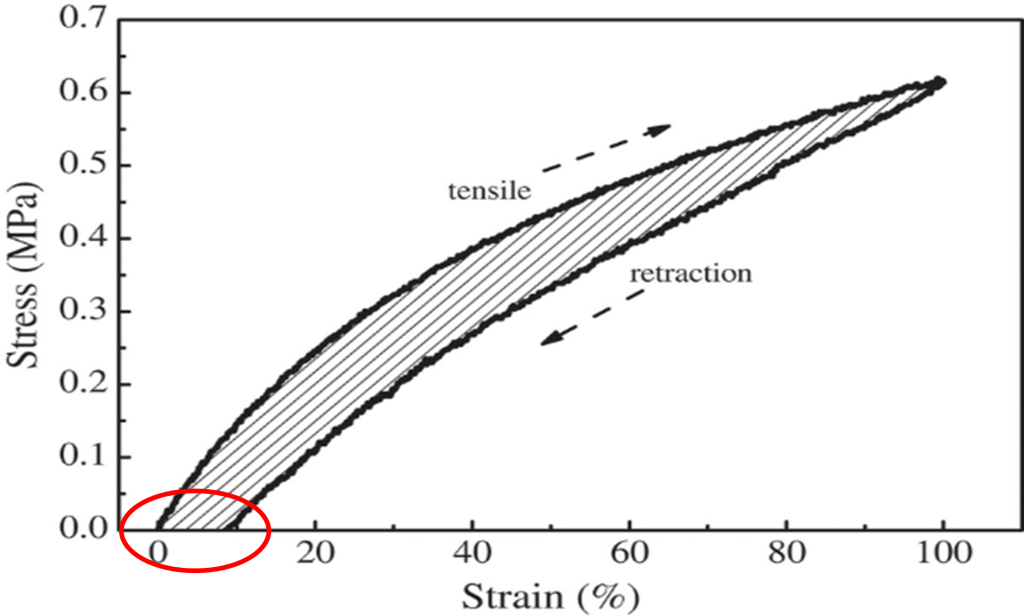

Hysteresis is a change in the static unloaded position which occurs after variation or cycling of a load on a structure.

All effects where relaxation or slip occurs due to load cycling lead to hysteresis, which means that the end position after load variation is different from the start position.

The effects causing instability can be divided in three effects:

Thermal drift

Thermal drift results from the fact that every material has a Coefficient of Thermal Expansion. Thermal gradients in time and/or over a construction lead to expansion or shrinkage and leads to a shift in position. Aluminum has typically 23∙10-6 m /K. So a bar of 1 m expands 23 μm due to a temperature change of 1 ∘C. Steel is typical 11∙10-6 m /K and invar is 0.5∙10-6 m /K Thermal effects are reversible effects. When after a +dT a -dT occurs. The systems returns to its original position.

An A-thermal design is a design which minimizes the thermal drift effects. Typical examples are thermal compensation or Thermal centre.

Dimensional drift or creep

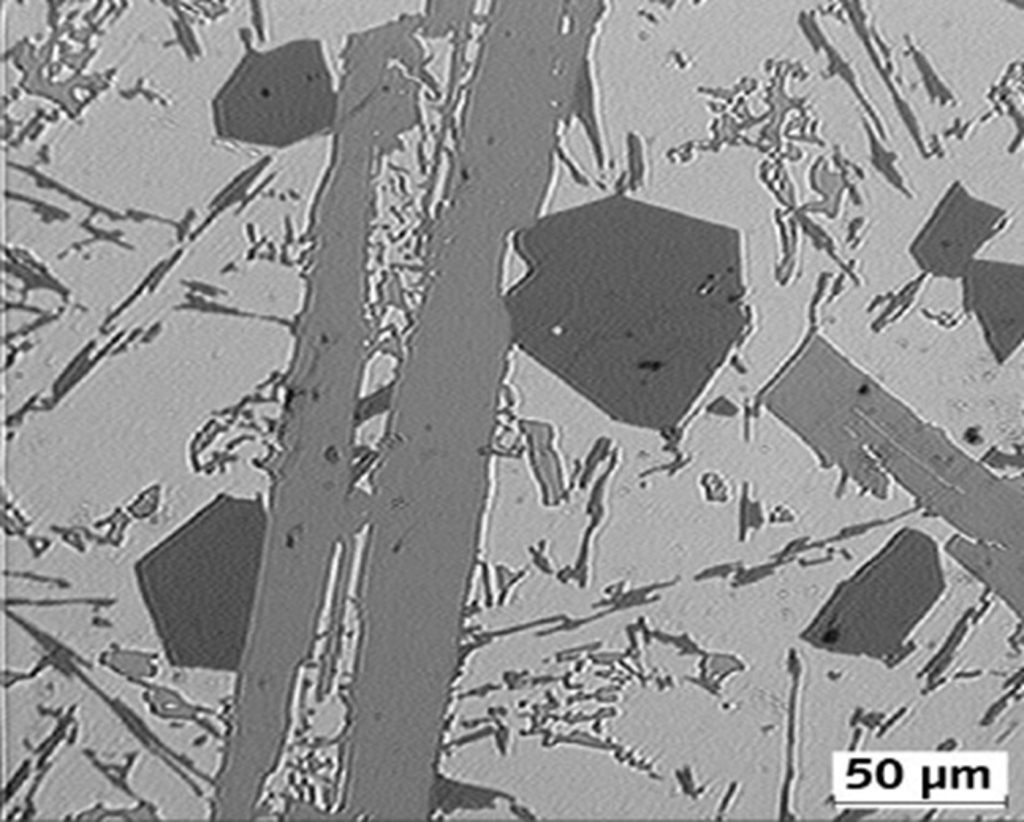

Dimensional drift is a material effect. It occurs due to release of internal stresses in materials. Stresses which can occur due to production of a part by e.g. machining, welding or soldering. The origin is based in the fact that materials are multi-crystalline. The internal material stresses are in general stresses among crystals. These internal stresses have a relaxation in time and can also be reduced by appropriate heat treatments. This effect is not reversable. These effects are mostly long term effects, though sometimes sudden release of internal stress occurs leading to snapping.

Structural drift or Creep

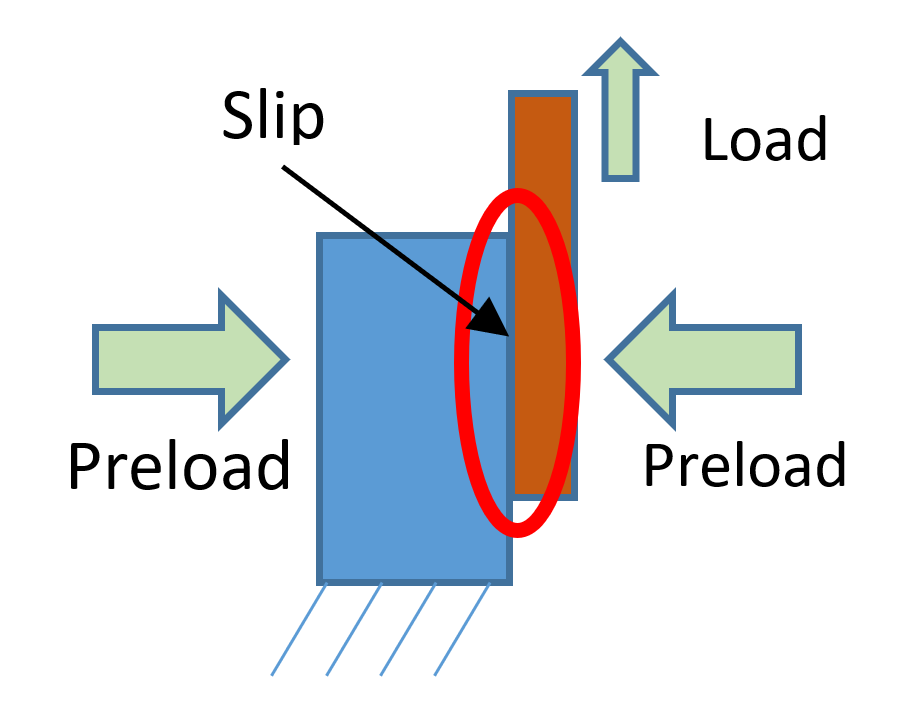

It refers to all drift effects related to assembly of a system, which can for example be clamping or mounting of two or more parts by bolting or welding or soldering. A clear example is a clamped leafspring. Difference in stiffness can lead to creep or hysteresis in the contacting surfaces of a clamped structure.

Load variations can induce a creep or snapping and can result in hysteresis.

Welding or soldering are more rigid connections and herewith will have more limited creep in the connection itself. The heatload due to the welding or soldering process will lead to deformation resulting in internal stresses, which can release in time.

Reference books:

- Basics of Precision Engineering, Smith and Leach

- Precision Engineering, Slocum

- Design Principles for Precision Engineering, Koster and Soemers: